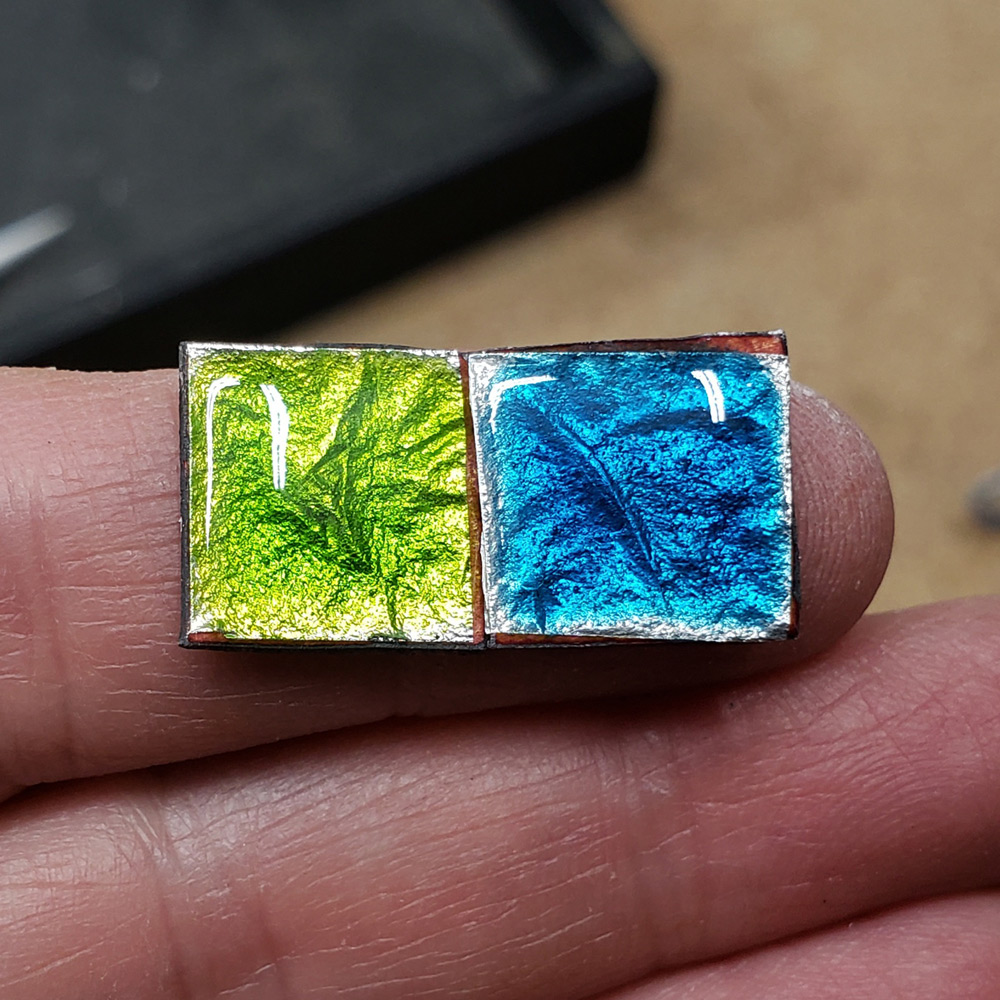

How did this start? Tangentially, like everything else in my life. A couple days ago, I was making test pieces of some of my new enamels.

Two of the pieces I made were particularly striking. These are Pearly Karpel's Kelly Green #463 and Blue Lake #213

… so I decided I wanted to make something with them. Then I remembered that I had been wanting do some testing to compare hand-finishing of cloisonné versus finishing using a JoolTool. My M.O. to date has kind of been to use both, but I want to isolate the methods in order to determine any differences. Also, I know a number of awesome enamellists who mention not liking to use the JoolTool in the finishing process. I don’t know if it’s because they just prefer other methods or if there’s something specific it does that is not good for the process.

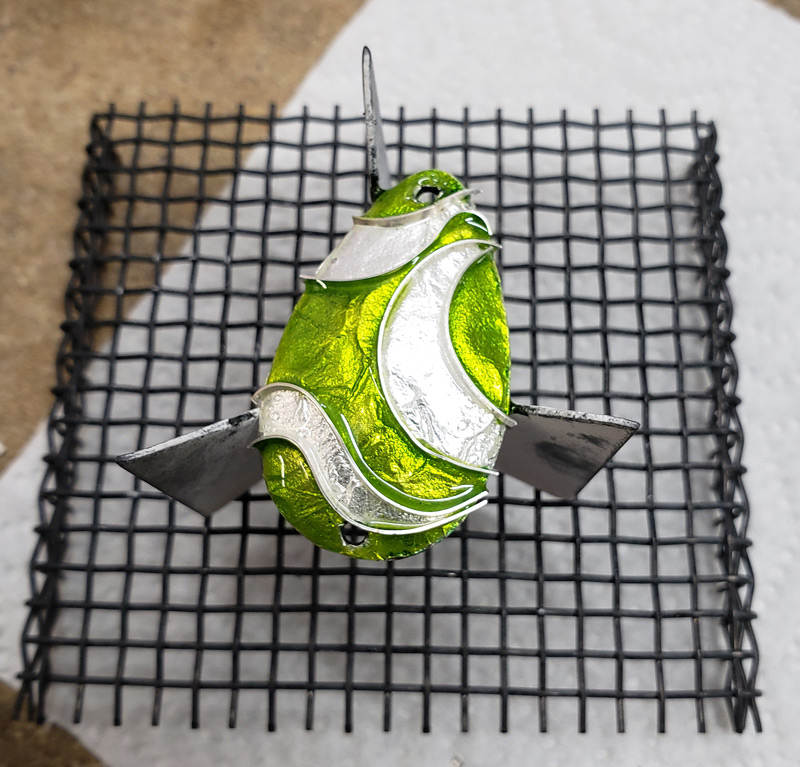

So I grabbed two thick copper pieces that I had in a bin, cleaned them, and gave them a counter-enamel. Then I created the fronts: flux and fire, silver foil and fire, flux and fire, cloisonné wires and fire, first layer of wet pack and fire, second layer of wet pack and fire, third layer of wet pack and fire, fourth layer of wet pack and fire.

I made both pieces similar (for comparison) but not identical.

When the enamel was at or just a smidge below the top of the wires, I began the two different finishing methods.

The first piece was finished all by hand, using only four different grits of diamond filing sticks (and water, or course).

After the 800 grit file, I washed the piece well before fire-polishing back in the kiln. Here are the results…

The first time I filed a cloisonné piece by hand, I learned the hard way that I was also taking off a certain amount of skin, mostly from my left thumb. Thanks to a friend, I learned about these awesome finger protectors at Otto Frei.

The piece looks good and feels smooth. I think I need to work on my hand filing, because the very center of the piece has less saturated color than the outer parts, leading me to believe when I file, I go over the center twice as often as I go over any other parts. Darn! Aw well… next time.

So then I took the second piece and finished it using the JoolTool. I only used the coarse, medium, and fine diamond sanding wheels (and water, of course).

As before, after sanding/polishing I cleaned the piece and put it back into the kiln for a fire polish.

If you follow me on Facebook, you have heard me say more than once that I am trying to learn cloisonné from books and online resources. There are limitations to that kind of learning, but I can’t take any in-person classes until the pandemic has abated so for now… there are pieces of the puzzle that are missing.

One such piece is… when I fire polish, my enamel sinks just enough to make the surface not feel like one smooth piece of glass anymore. Okay, so I can sand/polish it again… but then I have to fire polish it again and will run into the same problem.

Here are the three things I can think of to try to combat this problem. Other people end up with cloisonné that is smooth as glass and I want that too. It’s just an aesthetic difference, but I’d like to know I can do it.

I can try sanding/polishing with finer and finer grit (I have the option with both methods) and continue to fire polish hoping that as some point, things stay level.

I can try sanding/polishing by hand and NOT fire polish in the kiln.

I can sift a thin layer of clear over the whole surface and fire that to smoothness.

Just more experimenting. Also I may write a follow up blog post about the use of cerium oxide in the finishing process.

So what’s my conclusion? Hand filing might take longer but you can have more control. The JoolTool can be faster, but that goes hand in hand with accidentally removing something you didn’t intend to. And seriously, the way I do it there wasn't a huge time difference. Does that mean I know what I'm doing? No. But with my limited newbie knowledge, they took roughly the same amount of time.

Granted, I made my big error using the hand files, but I learned from that (don’t pass over the center so much!). Both pieces are very smooth on top (just the slight sinking of the enamel from the fire polishing as described above).

Also, note that I only sanded up to 800 grit with the diamond sanding sticks (the by-hand filing) while the JoolTools wheels may have given a higher grit effect (no clue what "grit" their "fine" is). I will be trying finer grit sanding on these pieces so stay tuned for that.

I’m sure I’m not skilled or knowledgeable enough to understand why some enamellists don’t like the JoolTool. Moving forward, and until proven otherwise, I may continue my hybrid method of using both the hand files and the JoolTool because at this moment I don’t see a difference.

I’m thinking that as I progress and refine my skills, maybe then I’ll have a more discerning opinion.